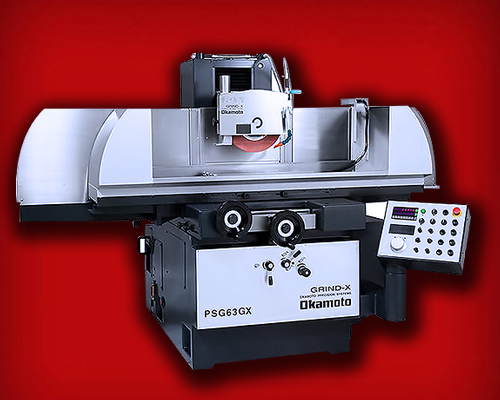

ACC GX SERIES

Overview

Smartest and Most Popular Standard & Leading Version of Surface Grinding Machine

in the World. Enjoying all-time high sales as single series and user's greatest credit due to

its balanced excellence in workmanship, manipulability and performance, and unrivalled

wide supply range. When it comes to Surface Grinding Machine, no one can miss OKAMOTO

in his reasonable choice.

Features :

- Rigid, double-walled column construction.

- Solid state ergonomically design control.

- Full width tables eliminate overhang.

- High precision wheel spindles with super-precision, pre-loaded bearings.

- Super-smooth table movement.

- Rapid Vertical Feed.

- Servo driven vertical feed.

ACC 52GX : Standard Chuck Size 500 x 200 mm.

ACC 63GX : Standard Chuck Size 600 x 300 mm.

ACC 64GX : Standard Chuck Size 600 x 400 mm.

ACC 65GX : Standard Chuck Size 600 x 500 mm.

ACC 84GX : Standard Chuck Size 800 x 400 mm.

ACC 105GX : Standard Chuck Size 1000 x 500 mm.

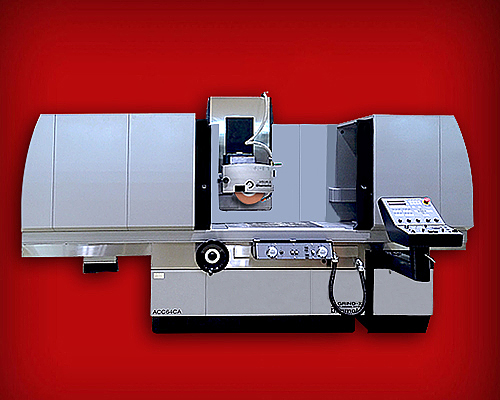

ACC CA SERIES

Overview

ACC-CA Series Grinders To ensure the highest accuracy and best ergonomic layout of

surface grinders with tables greater in width than 400 mm, Okamoto has continually

developed the moving column design.

Features :

- Column moving series suitable for lager workpieces

- Extremely rigid single piece Tee Shapes main casting

- Machine table supported on both sides at all times.

- The cross feed movement is supported on very rigid guide ways

-

The design of the column has been developed to guarantee very accurate

cross movement. - The double V (V-V) longitudinal slideway ensures accurate straightness

- Controls the amount of lubricating oil layer.

ACC 64CA : Standard Chuck Size 600 x 400 mm.

ACC 84CA : Standard Chuck Size 800 x 400 mm.

ACC 104CA : Standard Chuck Size 1000 x 400 mm.

ACC 66CA : Standard Chuck Size 600 x 600 mm.

ACC 106CA : Standard Chuck Size 1000 x 600 mm.

Overview

ACC CA-iQ Series Grinders These high-technology surface grinders feature super-rigid column feed design and construction to precisely grind large size components. They utilize Okamoto's exclusive iQ touch-control data input to deliver a new degree in simplicity, accuracy and performance.

Features :

- Double V longitudinal slide-way ensures accurate straightness

-

High rigid structure supports Cross feed movement on guide ways,

guarantees very accurate cross movements - Exclusive iQ Touch Screen Control with easy-to-use software

-

Extended saddle longitudinal ways reduce overhang for prolonged

machine life and accuracy. - Traveling Column Design provides easier access to work envelope

- Cover designed for the use of high pressure coolant systems

ACC 64CA-iQ : Standard Chuck Size 600 x 400 mm.

ACC 84CA-iQ : Standard Chuck Size 800 x 400 mm.

ACC 104CA-iQ : Standard Chuck Size 1000 x 400 mm.

ACC 66CA-iQ : Standard Chuck Size 600 x 600 mm.

ACC 106CA-iQ : Standard Chuck Size 1000 x 600 mm.

ACC SA1 SERIES

Overview

ACC-SA1 Series is a next standard surface grinder series equipped with

a newly developed user friendly controller for more capability and reliable ,

makes it easy to operate the machine.

Features :

- Best Machine For Replacement of PSG/ACC-DX Series.

- Position Teaching system for Crossfeed stroke.

- Compact Footprint Design.

-

New Control Allows For Easy Monitoring of Different lnformation

and LCD Touch Screen. - Auto Dress with Compensation is Standard.

- Spindle Inverter Unit is Standard.

- Auto-Retract Function is Standard.

ACC 52SA1 : Standard Chuck Size 500 x 200 mm.

ACC 63SA1 : Standard Chuck Size 600 x 300 mm.

ACC 64SA1 : Standard Chuck Size 600 x 400 mm.

ACC 65SA1 : Standard Chuck Size 600 x 500 mm.

ACC 84SA1 : Standard Chuck Size 800 x 400 mm.

ACC 105SA1 : Standard Chuck Size 1000 x 500 mm.

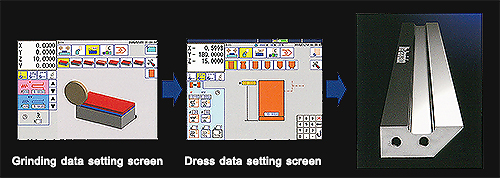

ACC CH-iQ SERIES

(DOUBLE COLUMN TYPE)

Overview

ACC-CH-iQ Series satisfies the demands for high accuracy required for machining

the progressive dies used for motor cores or LC processing, while also offering

the high efficiency needed by the die base processing industry.

Features :

-

Correspond High Accuracy demand or High Efficiency Grinding demand for

Progressive Die for Automotive motor core and LCD panel precision parts by

Double Column Type Surface Grinder. Succeed footprint and easy loading/unloading

style from longtime seller PSG208DXNC model, can be ground Max. 1000mm

width by adopt 100mm width grinding wheel. - There is no character in the operation screen, touch i-con and easy input.

-

The CH-iQ series was equipped with an automatic data making function

in a surface grinder for the first time. Input Total stock removal and Fine

Stock removal, and input wheel grid size, then can make the most suitable

grinding condition and dress condition. -

Further reduce cycle time by a combination of coarse grinding using

overhead dresser as option and finish grinding by table mount dresser,

besides shift-plunge contribute faster cycle time. -

Further reduce cycle time by a combination of coarse grinding using

overhead dresser as option and finish grinding by table mount dresser.

ACC 208CH-iQ : Table working area 2050 x 850 mm.

ACC 258CH-iQ : Table working area 2550 x 850 mm.

ACC 358CH-iQ : Table working area 3550 x 850 mm.

ACC DX SERIES

( Column type )

Overview

ACC-DX column type grinders are specifically designed and built to deliver

rugged performance, superb accuracy and long term dependability

at an affordable price. They utilize Okamoto's exclusive control system

that simplifies grinding of large components.

Features :

-

Column traveling type is independent table Longitudinal and the column

crossfeed, the workpiece no need to move crossfeed.The positional relationship

between workpiece with operator is always the same which provides excellent

operability. -

Table Longitudinal drive has adopted the overhang-less design. Stable grinding

accuracy without staggering even when reversal of heavy weight workpiece. -

Integrate type operation panel design based on human engineering easy and

user friendly with necessary interlock build-in. -

Incorporating own developed software is easy to set up full automatic cycle

like a . "Coarse grinding ⇒ Fine grinding ⇒ spark out ⇒ table right end stop".

Grinding conditions are set by digital switch, with confirmation, manual

interruption during cycle is also available.When manual interrupt current

infeed positioning always feedback and display correctly, as soon as release

manual interruption return to Auto grinding mode and grinding remaining stock.

ACC 125DX : Table working area 1250 x 500 mm.

ACC 155DX : Table working area 1550 x 500 mm.

ACC 205DX : Table working area 2050 x 500 mm.

ACC 305DX : Table working area 3050 x 500 mm.

ACC 126DX : Table working area 1250 x 600 mm.

ACC 156DX : Table working area 1550 x 600 mm.

ACC 206DX : Table working area 2050 x 600 mm.

ACC 306DX : Table working area 3050 x 600 mm.

ACC 157DX : Table working area 1550 x 700 mm.

ACC 138DX : Table working area 1350 x 800 mm.

ACC 158DX : Table working area 1550 x 800 mm.

ACC 208DX : Table working area 2050 x 800 mm.

ACC 308DX : Table working area 3050 x 800 mm.